수탁사업

/ Hydrogenation /

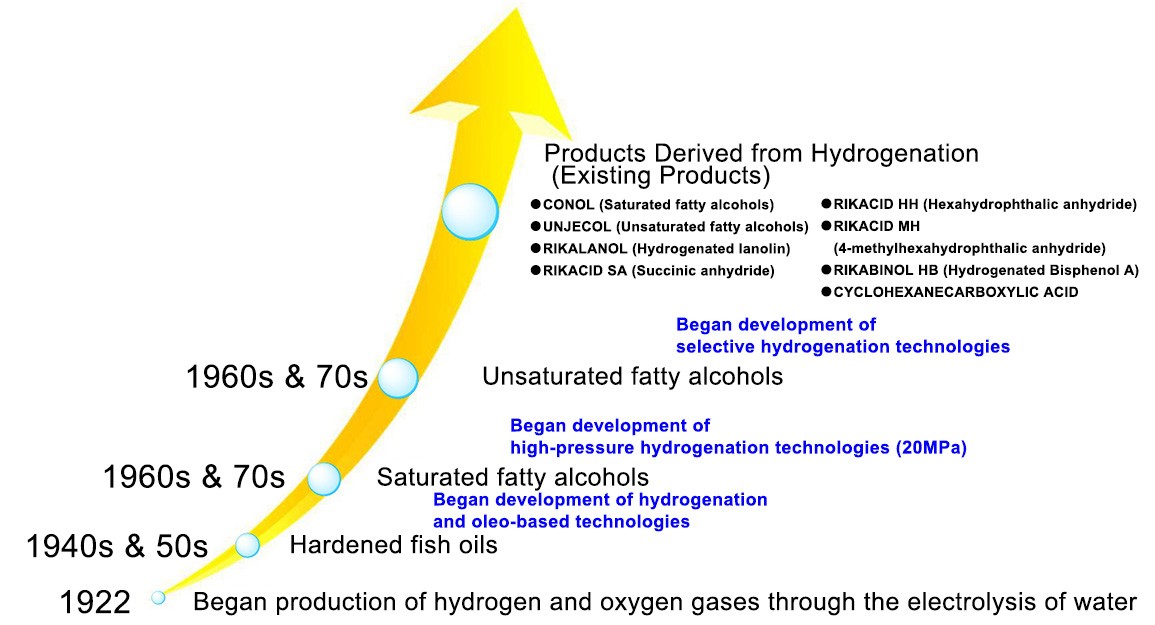

In 1919, we began manufacturing and selling oxygen gas derived through the electrolysis of water. At the time, we asked ourselves if there was some way to use the hydrogen gas produced as a byproduct of this process.

This initial spirit of conservation and desire to eliminate waste is what led us to develop our hydrogenation technologies. Now, 100 years later, we are still working to provide products and services by harnessing the vast potential of hydrogenation.

We provide custom services for hydrogenation reactions, including high-pressure hydrogenation and hydrogenation controlling for cis/trans isomers. Each solution harnesses our own in-house technologies and is matched to the client's specifications. Feel free to contact us for any of your hydrogenation needs.

Process for Commissioning Work

① Signing a Non-disclosure Agreement

We will conclude a non-disclosure agreement with the client upon request.

② Discussion of Details

We will discuss with the client about details such as the desired product, quality, and amounts for their order.

③ Laboratory Examinations

We will conduct surveys on raw materials, review relevant research and studies, and execute composite laboratory examinations.

When the client has disclosed their formulation to us, we will conduct confirmatory experimentation based on their formulations.

In either case, we will make sure to optimize the formulation according to specifications of our equipment and machinery.

④ Client Assessment (Quality & Cost)

Based on the results of our lab examinations, we will provide a calculation of preliminary costs and price.

Upon request, we can also provide a small sample of the results obtained from our lab examinations.

⑤ Discussion of Quality Standards

We will hold discussions on quality standards based on the results of the lab examinations and client assessment.

⑥ Compliance with Relevant Laws and Regulations

We will provide support by filing applications for small quantities of new chemical substances and other legally mandated documents in compliance with relevant laws and regulations (Chemical Substances Control Law, Industrial Safety and Health Act, etc.).

⑦ Mass Production

We will begin manufacturing the client's order using our mass production equipment based on optimized formulations (production fees will be charged).

⑧ Delivery

We will deliver the finished product according to the agreed quality standards.

The Relationship Between New Japan Chemical & Hydrogenation

At New Japan Chemical, our first work with hydrogenation began 100 years ago. Our numerous products available on the market still to this day were created using our hydrogenation techologies. And we continue to develop these technologies for both the products of today and the future.

Features behind New Japan Chemical's Hydrogenation Technologies

- A long record of performance and extensive knowledge, experience and technical expertise built up 100 years

- Supports high pressure hydrogen gas (batch: ~5MPa/continuous: ~20MPa)

- A diverse lineup of equipment and devices (batch and continuously-operating devices)

- Supports a wide range of quantities (from hundreds of kilograms to thousands of tons)

- Possible to commission pre and post processing operations for crystallization, distillation, and other reactions

Batch-type High Pressure Reaction Facilities

*In addition to the above batch-type facilities, we also carry facilities for continuous high-pressure reactions.

Distillation Facilities

Reaction & Crystallization Facilities

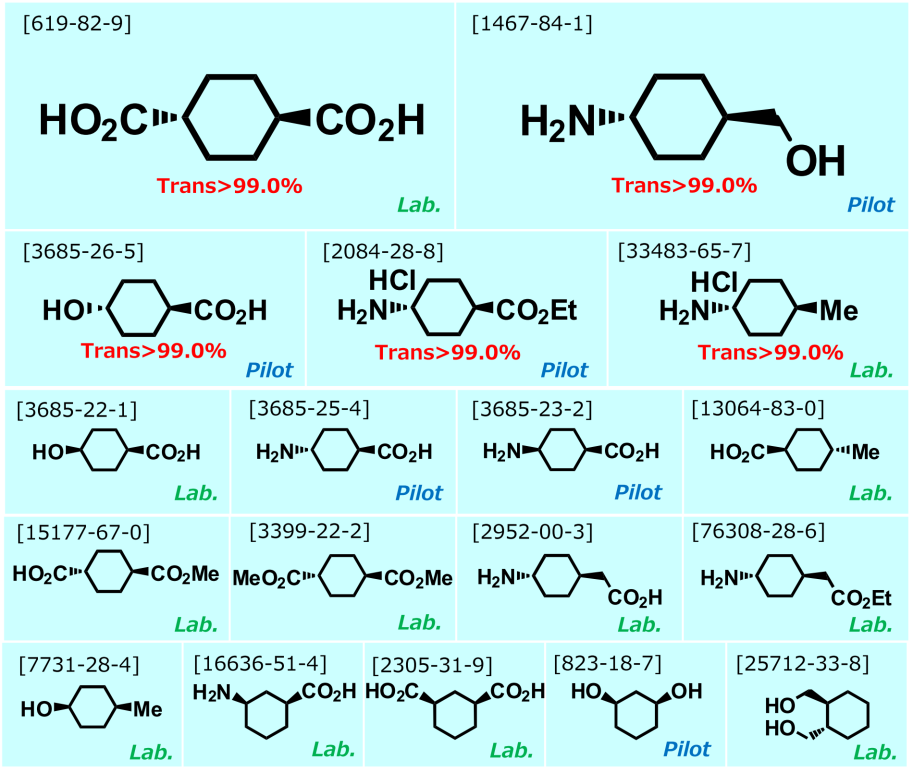

Examples of New Japan Chemical's Hydrogenation Reactions

Below you will find some examples of existing products as well as products under development. We have also worked on numerous other hydrogenated products in addition to these.

Please contact us for solutions to all your hydrogenation needs.

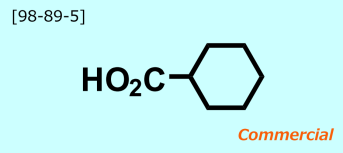

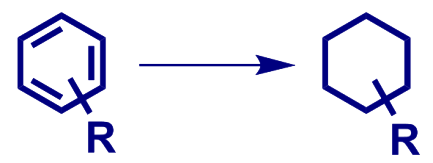

Hydrogenation of Aromatic Rings

In general, the hydrogenation of aromatic rings requires a stricter set of conditions (high pressure) than hydrogenation of double and triple bonds. At New Japan Chemical, we are able carry out the hydrogenation of aromatic rings using a high-pressure hydrogen gas.

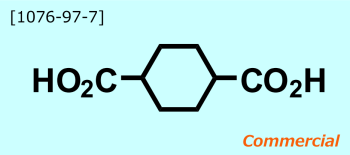

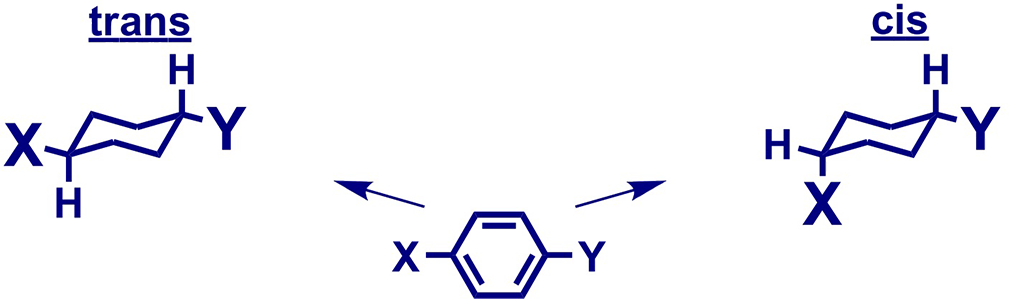

Cis/trans Selective Hydrogenation

When hydrogenating aromatic rings with multiple substituents, we generally get a mixture of cis/trans isomers.

However, most cases only require one of these isomers. New Japan Chemical is capable of individually creating pure cis/trans cyclohexanes.

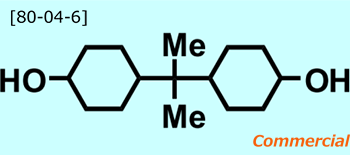

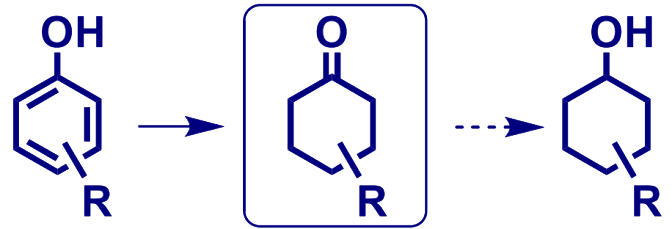

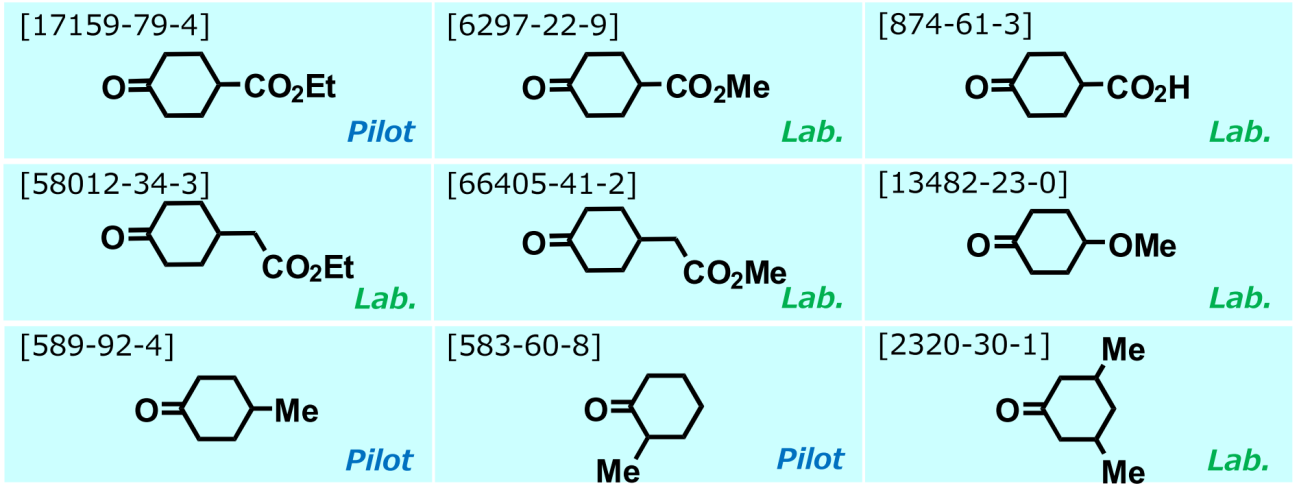

Partial Hydrogenation of Phenol Rings

Cyclohexanols are generally derived from the hydrogenation of the phenol rings.

At New Japan Chemical, we optimize conditions for the hydrogenation of phenol rings, allowing for the selective acquisition of the cyclohexanones that form the reaction intermediate.

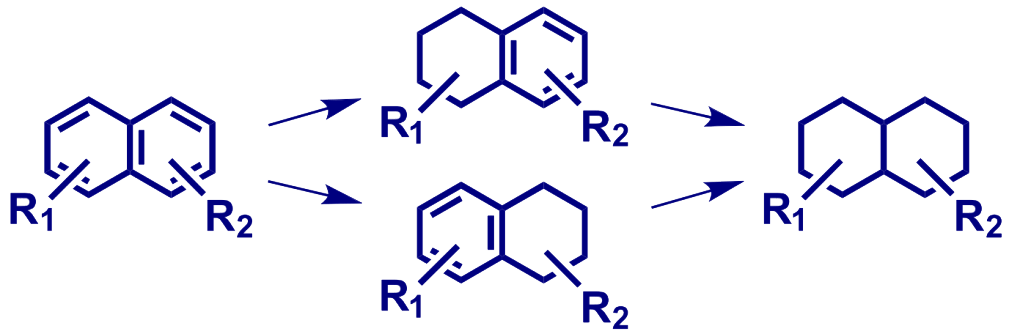

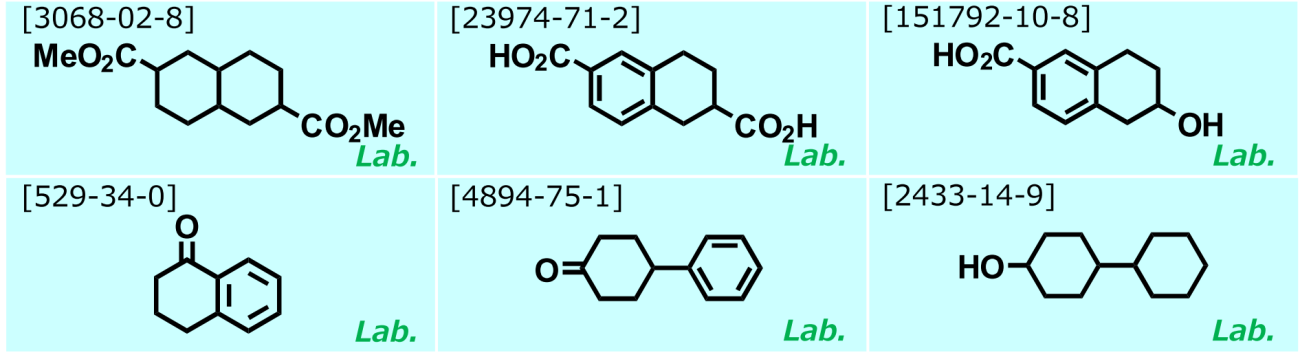

Selective Hydrogenation of Polycyclic Aromatic Compounds

At New Japan Chemical, we are able to carry out selective hydrogenation on one or all of the rings in polycyclic aromatic compounds.

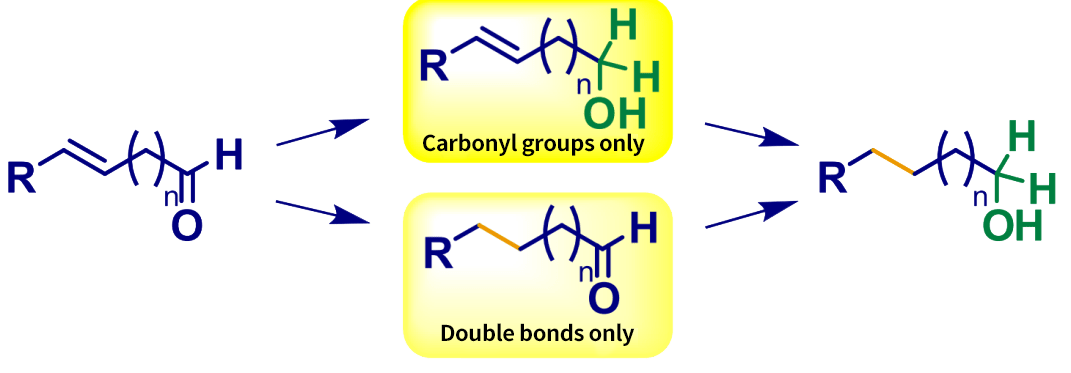

Chemoselective Hydrogenation

Hydrogenating a single target while leaving the other untouched presents a significant challenge when hydrogenating multiple functional groups within a molecule.

For compounds containing double bonds and carbonyl groups, we at New Japan Chemical are able to carry out selective hydrogenation for both the highly reactive double bonds as well as the comparatively less reactive carbonyl groups.

Likewise, we can conduct selective hydrogenation on either double bonds or ester groups when these are contained in a compound.